When we think about hospital beds, the comfort and safety they provide often come down to what’s happening behind the scenes — especially the linear actuator system. This system quietly works to adjust beds smoothly, helping patients find the right position and making a nurse’s job easier.

But what exactly makes a linear actuator system “hospital-grade”?

Let’s talk about the key features that set these systems apart, focusing on the Indian hospital environment — where reliability, durability, and adaptability are non-negotiable.

What Is a Hospital-Grade Linear Actuator System?

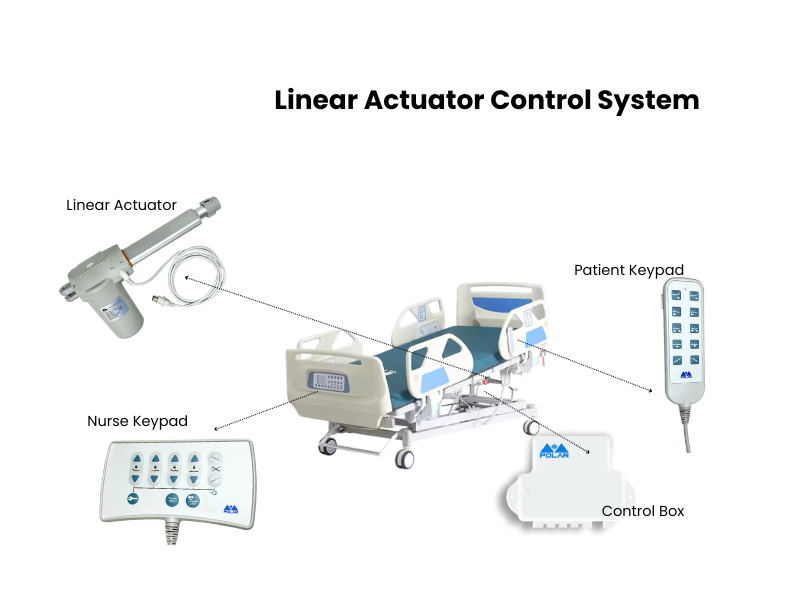

At its simplest, a linear actuator system is a combination of smart components that work together:

- The linear actuator moves the bed smoothly, usually powered by a 12V actuator motor.

- The control box acts as the brain, controlling the actuator’s movements.

- The patient handset or bed remote allows patients to adjust their bed positions independently.

- The nurse keypad gives caregivers more control and special functions.

Together, these parts make flexible and user-friendly. However, hospital-grade systems go way beyond basic functionality.

Key Features of a Hospital-Grade Linear Actuator System

1. Customization in Linear Actuator Control Systems for Hospital Use

No two hospitals or beds are exactly the same. Therefore, hospital-grade systems offer customization — from the size and shape of the linear actuator control box to the layout of buttons on the patient handset and nurse keypad. As a result, the system fits perfectly and feels intuitive for both patients and staff.

2. Smart Linear Actuators: Quiet Performance in Medical Settings

In addition, a smart linear actuator system ensures quiet operation — a must in hospital environments. These actuators are built to last, handle frequent use, and maintain precision — even after thousands of adjustments. Consequently, patients experience comfort without disturbance.

3. What Is the Role of Microcontrollers in Linear Actuator Systems?

You might wonder, “What is the primary role of microcontrollers in medical devices?” In these actuator systems, microcontrollers are tiny but powerful brains. They ensure that commands from the bed remote or nurse keypad are executed safely and accurately. Moreover, they prevent sudden jerks or overloads, protecting both patients and equipment.

4. Safety Standards in Medical Linear Actuator Systems

Safety isn’t an add-on; it’s built into the system. Hospital-grade actuators and control boxes meet strict electrical and mechanical standards. In contrast to generic actuators, these are designed to handle power fluctuations common in India. Additionally, built-in fail-safe features offer protection during emergency situations.

5. Why Support Matters for Hospital Linear Actuator Systems

Not only that, a great design isn’t enough without strong support. Managing design, manufacturing, and dispatch under one roof ensures consistent quality and faster turnaround. As a result, hospitals benefit from quick service and reduced downtime.

Why These Features Matter in the Indian Market

Indian hospitals often deal with power instability, varied bed models, and tight budgets. Therefore, a linear actuator system must be efficient, adaptable, and cost-effective.

- The popular 12V actuator balances power and safety.

- Customizable linear actuator control boxes support diverse bed models.

- Durable, smart electric actuators handle repetitive use with ease.

- Furthermore, well-designed bed remotes and nurse keypads improve usability in high-pressure hospital environments.

The term “hospital-grade” goes beyond tough hardware. Ultimately, it’s about building a system that’s reliable, safe, and user-friendly.

When microcontrollers work silently in the background, actuators move gently, and the control box responds instantly — then you know it’s a truly hospital-grade linear actuator system.

Add a Comment