In today’s industrial automation landscape, precision, flexibility, and safety are crucial. A wireless actuator control system provides advanced control over linear actuators, enabling remote operation, simplified installation, and improved efficiency. Moreover, this system integrates seamlessly with 24V DC industrial actuators and external actuator control units, making it ideal for manufacturing, medical equipment, and smart industrial setups.

What is a Wireless Actuator Control System?

A wireless actuator control system is a technology solution that allows operators to control linear actuators remotely. Specifically, it consists of:

- A linear actuator controller or wireless actuator controller that manages actuator motion.

- An actuator control box or external actuator control unit that regulates power and communicates with actuators.

- Industrial actuators, typically 24V DC, that deliver precise motion.

Consequently, operators can control multiple actuators wirelessly, enhancing both precision and safety in industrial operations. Furthermore, the system reduces wiring complexity, which lowers installation time and costs.

Key Features of Wireless Actuator Control Systems

Wireless actuator control systems offer a range of features that improve industrial performance.

1. Remote Operation

Firstly, a wireless actuator control system eliminates the need for extensive wiring. As a result, operators can control actuators from safe distances. This feature is particularly valuable in hazardous or hard-to-reach environments.

2. Precise Motion Control

Moreover, modern linear actuator controllers provide accurate positioning, adjustable speed, and programmable travel limits. Consequently, production processes achieve higher efficiency and consistency.

3. Flexible Power Options

In addition, many systems support 24V DC actuators, ensuring reliable power and safe operation. The external actuator control unit optimizes power delivery and protects actuators from overload or damage.

4. Compatibility with Multiple Actuator Types

Similarly, wireless actuator controllers are compatible with a variety of industrial actuators, including rod-style, telescopic, and lifting column actuators. Therefore, the system is highly versatile across applications.

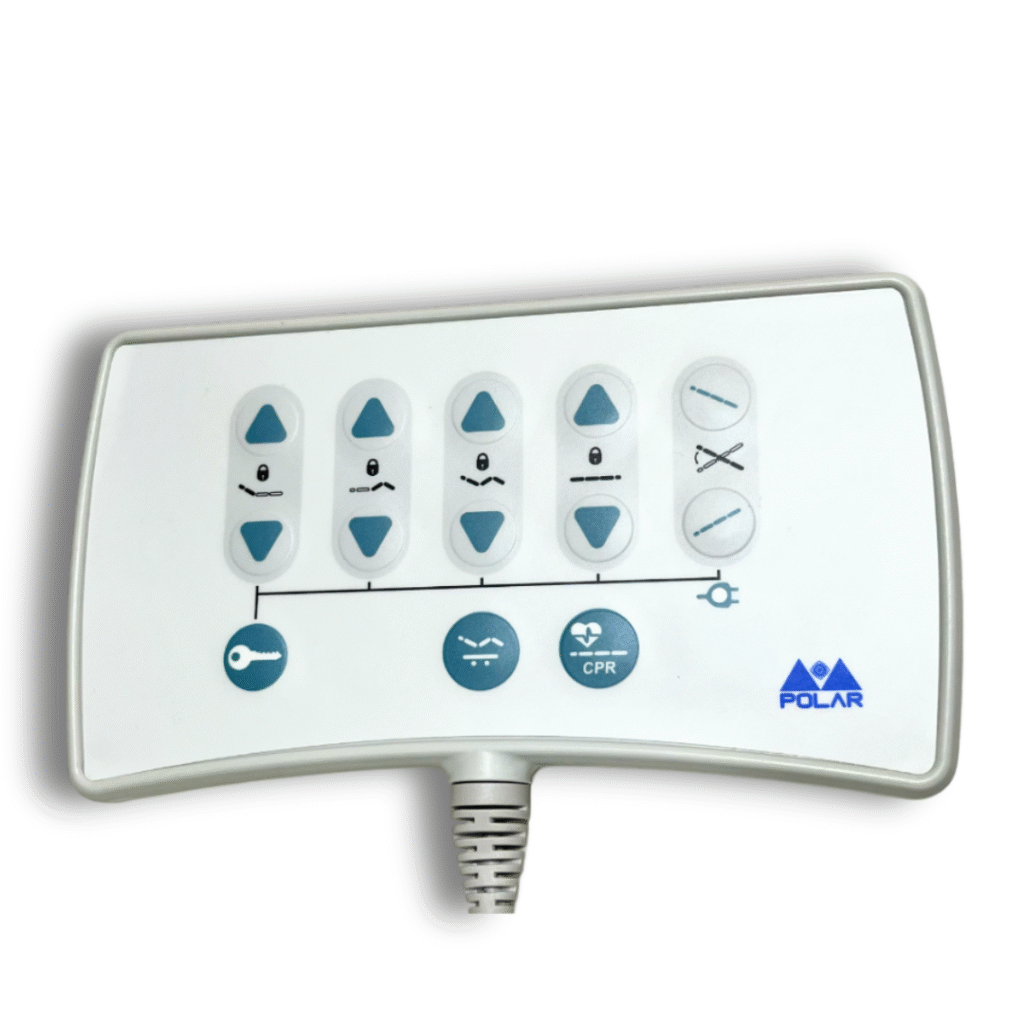

5. User-Friendly Interface

Furthermore, operators can monitor and control actuators via a mobile or desktop interface. For instance, programmable sequences allow repetitive tasks to be automated, saving time and reducing errors.

6. Safety and Feedback Features

Additionally, wireless systems include overload protection, emergency stop functions, and real-time feedback. Consequently, operators can prevent actuator damage and ensure operational safety.

Benefits of a Wireless Actuator Control System

Implementing a wireless actuator control system offers significant advantages compared to traditional wired systems.

1. Simplified Installation

Firstly, without complex wiring, installation becomes faster and cleaner. Therefore, retrofits or system upgrades are more convenient, reducing downtime.

2. Reduced Maintenance

Moreover, fewer physical connections mean lower wear and tear. As a result, wireless actuator systems are less prone to environmental damage from dust, moisture, or chemicals.

3. Enhanced Safety

In addition, remote operation keeps personnel away from moving machinery. Consequently, operators are less exposed to risks, while instant feedback ensures timely alerts for faults or overloads.

4. Scalability

Furthermore, wireless actuator control systems are easily expandable. For instance, additional actuator control boxes or controllers can be added as production needs grow.

5. Energy Efficiency

Similarly, the external actuator control unit optimizes energy usage for 24V DC industrial actuators. Therefore, operational costs are reduced while maintaining performance.

6. Improved Automation Precision

Additionally, automated sequences, speed adjustments, and programmable positioning reduce human error. As a result, production quality improves and consistency is maintained across operations.

Industrial Applications of Wireless Actuator Control Systems

Wireless actuator control systems are highly versatile and find use in various industrial and commercial sectors.

1. Automated Manufacturing

For example, wireless systems control robotic arms, conveyor belts, and assembly lines. Consequently, operators can manage multiple actuators simultaneously, enhancing production efficiency.

2. Material Handling

In warehouses, wireless actuator control systems operate lift platforms, sorting machinery, and automated storage systems. Therefore, material handling becomes safer and more efficient.

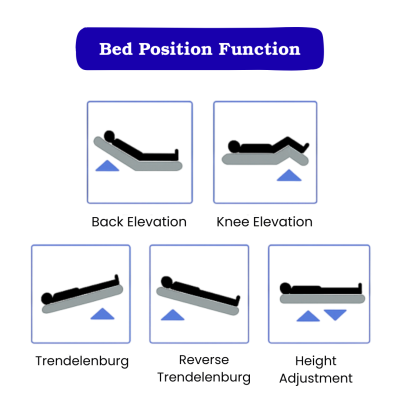

3. Medical Equipment

Similarly, adjustable hospital beds, patient lifts, and diagnostic machines benefit from wireless control. In addition, operators can ensure precise movement without physical intervention.

4. Agricultural Automation

For instance, greenhouses, irrigation systems, and farm machinery integrate wireless actuator controllers to optimize environmental conditions. Consequently, labor is reduced, and productivity increases.

5. Renewable Energy Systems

Moreover, solar panel trackers and wind turbines use wireless actuator control systems for optimal positioning. As a result, energy generation becomes more efficient and consistent.

6. Smart Industrial Equipment

Finally, wireless actuator controllers enable IoT integration, real-time monitoring, and automated adjustments. Therefore, smart factories and Industry 4.0 setups achieve higher efficiency and automation precision.

Choosing the Right Wireless Actuator Control System

When selecting a wireless actuator control system, several factors must be considered:

- Actuator specifications: stroke length, voltage (24V DC), and load capacity.

- Control features: programmable sequences, speed control, limit switches, and feedback integration.

- Communication protocols: RF, Bluetooth, or proprietary wireless systems.

- Environmental factors: dust, moisture, temperature, and interference.

- Scalability: the ability to expand with additional actuators or actuator control boxes.

Consequently, choosing the right system ensures reliability, efficiency, and future-proof automation.

Conclusion

A wireless actuator control system transforms industrial automation by offering remote operation, precise motion control, and reduced maintenance. Furthermore, features such as compatibility with linear actuators, 24V DC devices, and external actuator control units make it superior to traditional wired systems.

From manufacturing and material handling to medical, agricultural, and renewable energy applications, wireless actuator controllers and actuator control boxes provide enhanced productivity, safety, and scalability. Therefore, investing in a wireless actuator control system is a strategic step toward smarter, more efficient industrial operations.