Precise Handling, Reliable Performance

SmaSmart Motion Solutions for Material Handling Equipment

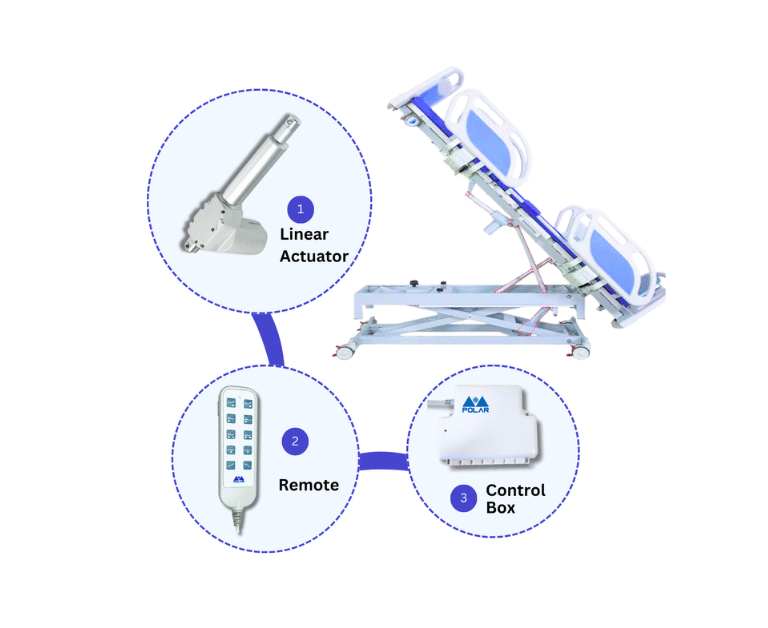

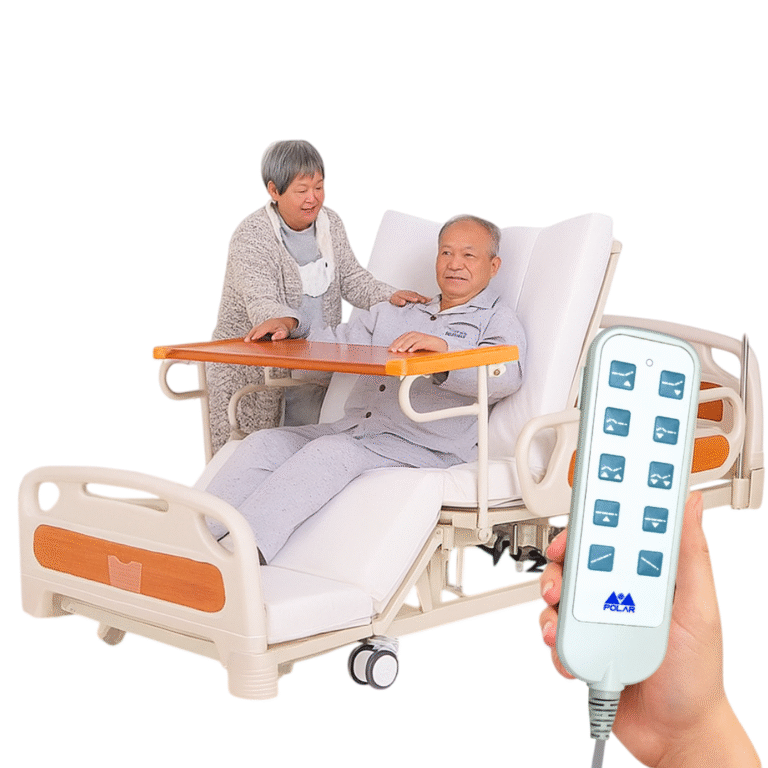

Our linear actuator control system delivers smooth, strong, and accurate motion for material handling equipment, optimizing load positioning, lifting, and transportation with intelligent electronic control designed for high-demand industrial environments.

AUTOMOTION SYSTEMS

Streamlining Efficiency and Productivity with Advanced Material Handling Solutions

At Polar Automation, we specialize in material handling systems that optimize the movement, storage, control, and protection of materials throughout the manufacturing and distribution processes. Whether you're managing raw materials in a warehouse, processing goods in an industrial facility, or shipping products for retail, our automation solutions can help you increase operational efficiency, reduce costs, and ensure the safe movement of goods.

What Are Material Handling Systems?

Material handling systems refer to the equipment, machinery, and software that automate the movement, storage, control, and protection of materials within an environment such as a factory, warehouse, or distribution center. These systems are designed to manage everything from raw materials to finished products, ensuring smooth and continuous workflows.

Our material handling systems include a range of equipment and technologies such as:

Conveyor Systems

Automated conveyor belts or rollers designed to move goods efficiently through production lines or warehouses.

Automated Guided Vehicles (AGVs)

Self-driving vehicles that transport materials throughout a facility without human intervention.

Storage Solutions

Automated shelving, pallet racks, and other systems that improve storage efficiency.

Robotic Arms and Pickers

Robots designed to handle, assemble, and store materials with high precision and speed.

Vertical Lift Modules (VLMs)

Automated storage systems that maximize vertical space for storing parts or products, improving accessibility and reducing floor space usage.

These systems can be integrated into any part of your facility, from receiving and sorting materials to shipping finished products to customers.

Types of Material Handling Systems

Depending on your specific requirements, we offer a variety of material handling solutions, including:

Automated Storage and Retrieval Systems (ASRS)

These systems automatically place and retrieve items from storage locations using machines like cranes, lifts, and shuttles. ASRS improves inventory control, reduces manual labor, and maximizes storage space efficiency.

Conveyor Systems

- Belt Conveyors: Used for transporting bulk materials or packaged products smoothly over a set path.

- Roller Conveyors: Ideal for handling heavier items or larger volumes in warehouses or distribution centers.

- Overhead Conveyors: Useful for light and medium-weight products, especially in factories or processing plants.

Automated Guided Vehicles (AGVs)

These are autonomous, self-guided machines designed to transport materials across the floor. AGVs reduce the need for forklifts or manual labor, minimizing the risk of accidents while improving efficiency.

Robotic Pick and Place Systems

Robotic arms and automated pickers handle material placement and packaging tasks with precision. This type of system is commonly used in assembly lines, warehouses, and distribution centers.

Industrial Lift Systems

Designed to move heavy loads vertically, industrial lifts can be used in conjunction with automated guided vehicles or conveyor systems to reduce downtime and increase productivity.

Palletizing Systems

These systems are used for efficiently stacking items onto pallets for storage or shipping. Automated palletizers increase speed and reduce human error in high-volume production environments.

Benefits of Material Handling Systems

Implementing material handling systems in your facility brings significant benefits, improving both efficiency and safety. Here’s how:

Increased Efficiency

Automated material handling systems can significantly reduce the time it takes to move products from one point to another, reducing delays and increasing throughput.

Reduced Labor Costs

Automation reduces the need for manual labor, allowing staff to focus on more valuable tasks while the systems handle the heavy lifting.

Enhanced Accuracy and Reduced Errors

With automated systems, you reduce human errors in handling, such as incorrect stock placements or missed shipments, leading to better inventory control and customer satisfaction.

Improved Safety

By reducing the need for manual handling and lifting, you decrease the risk of injuries caused by accidents. Material handling systems are also designed with safety features like sensors to prevent collisions.

Optimized Space Utilization

Automated storage and retrieval systems, along with vertical lift modules, allow you to maximize available space, increasing storage capacity without expanding your facility.

Scalability

Our systems can be customized and scaled to fit your growing business needs, whether you’re managing a small warehouse or a global supply chain network.

Why Choose Polar Automation’s Material Handling Solutions?

At Polar Automation, we design and implement material handling systems that are tailored to your business needs. Here’s why our solutions stand out:

Customized Solutions

We work closely with you to understand your unique requirements and design material handling systems that fit perfectly within your existing infrastructure.

Innovative Technology

We use the latest in automation technology, ensuring that your system operates with maximum efficiency and minimal downtime.

High-Quality and Reliable

Our systems are built to last, with durable components that stand up to even the most demanding environments, ensuring long-term reliability.

Expert Support and Maintenance

Our team of experts provides end-to-end support, from system design and installation to maintenance and upgrades, ensuring your system continues to perform at its best.

Applications of Material Handling Systems

Material handling systems are versatile and applicable across a wide range of industries, helping businesses of all sizes streamline their operations. Some common industries where our systems are used include:

- Manufacturing: For moving raw materials, components, and finished goods through production lines and assembly areas.

- Warehousing and Distribution: To manage inventory and optimize the picking, packing, and shipping of goods.

- E-commerce: Helping online retailers automate the sorting and packaging of products for faster fulfillment.

- Food and Beverage: For safely and efficiently moving raw ingredients and packaged products while maintaining hygiene standards.

- Automotive: Moving automotive parts and components through assembly lines, reducing manual labor and improving productivity.

Industry Experts

Our custom automated solutions combine cross-industry know-how, powerful in-house capabilities, a new generation of intuitive control systems.

Share your Details and we will call you back!

Feel free to share your information, we would like to consult with your projects.