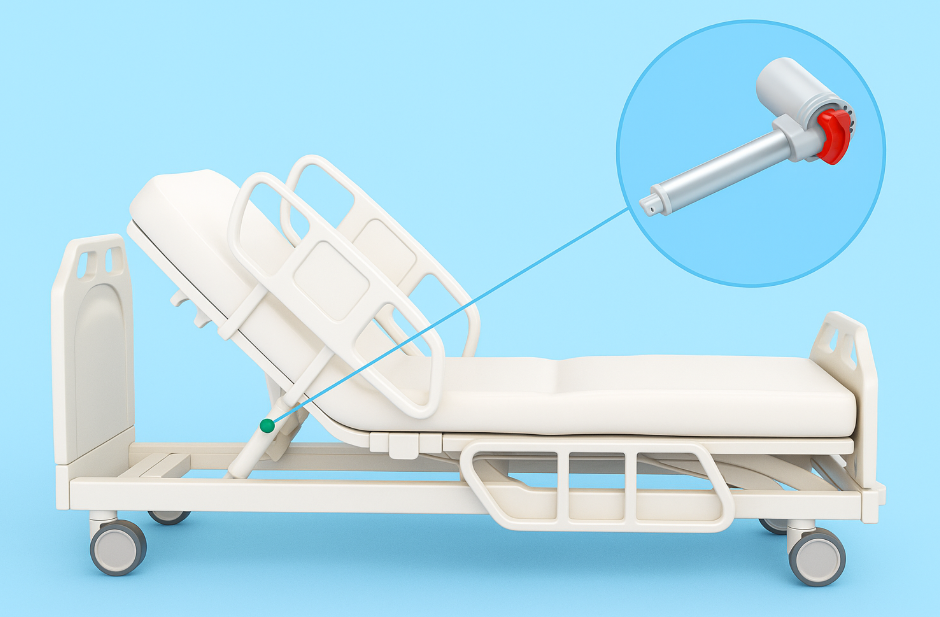

In today’s healthcare environment, hospitals and medical equipment manufacturers depend on technologies that deliver accuracy, reliability, and long operational life. At the center of modern hospital furniture automation is the hospital beds linear actuator, a system that must offer smooth motion, long-term durability, and precise control.

Polar Automation has become a preferred partner for medical bed OEMs because of its consistent engineering quality, deep understanding of hospital equipment requirements, and commitment to future-ready automation solutions.

Hospital Beds Linear Actuator Designed for Precise Medical Bed Movements

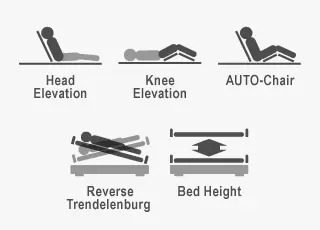

A hospital beds linear actuator must perform flawlessly during frequent adjustments. Polar’s systems are designed to offer:

- Smooth and silent motion, ensuring comfort for patients and ease for caregivers.

- Accurate position control, allowing medical teams to set and maintain the exact posture required for treatment, therapy, or patient support.

- Consistent repeatability, ensuring each movement follows precise alignment, even after years of continuous use.

This level of precision comes from carefully engineered motors, optimized gear mechanisms, and intelligent control electronics developed in-house.

Designed for Long-Term Reliability in Demanding Environments

Hospital beds operate around the clock. Every component within the motion system must withstand continuous use without performance drops. Polar builds its actuator systems with:

- High-grade materials selected for strength and corrosion resistance.

- Industrial-quality motor designs built for long duty cycles.

- Thermal and load protection mechanisms to prevent system strain during peak usage.

This ensures a long service life, fewer replacements, and stable functioning even in busy hospital environments.

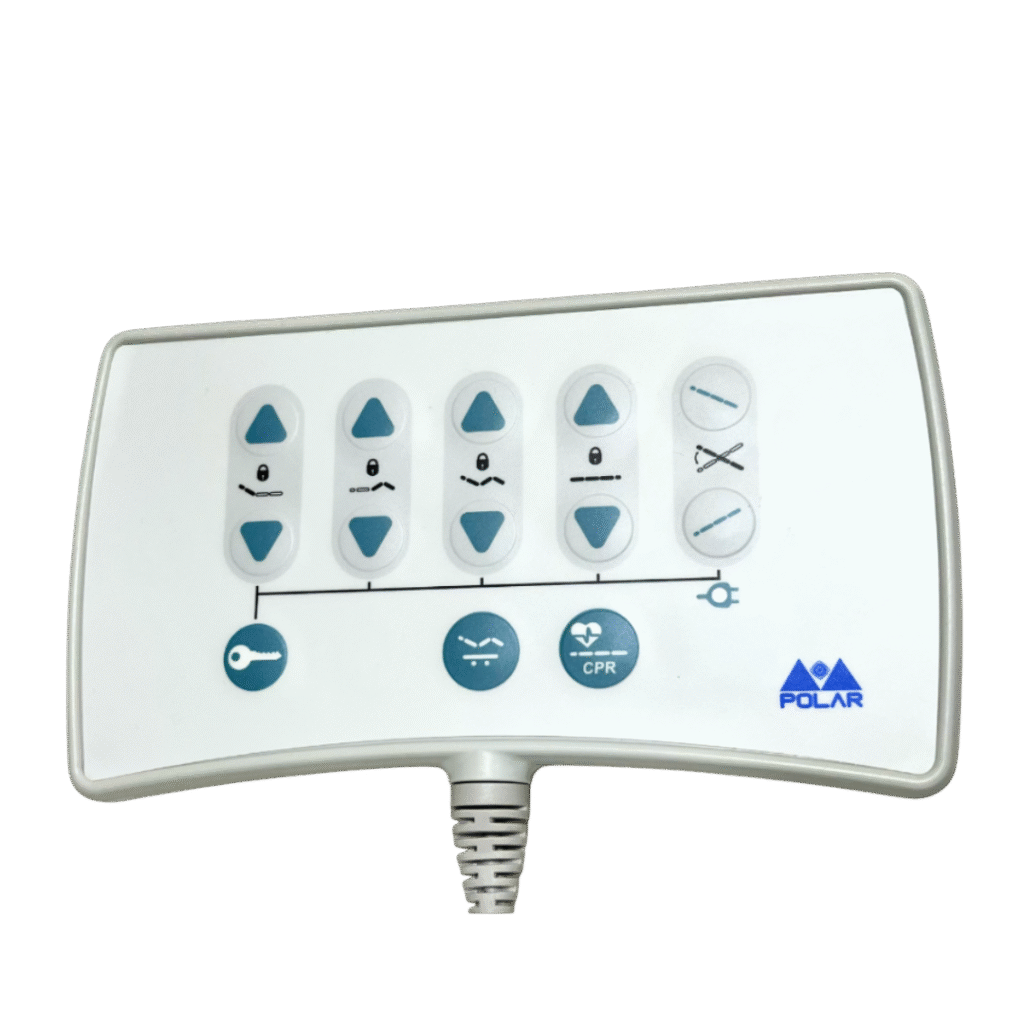

Built-In Safety Aligned With Medical Industry Expectations

Safety is one of the strongest requirements in healthcare automation. Polar integrates protective features directly at the hardware and control levels, including:

- Overload protection to prevent damage during unexpected force.

- Safe-stop logic for controlled movement in case of power variations.

- Medical-grade compliance design focused on reliability and fail-safe operation.

These elements contribute to safer patient handling and secure bed adjustments in critical care scenarios.

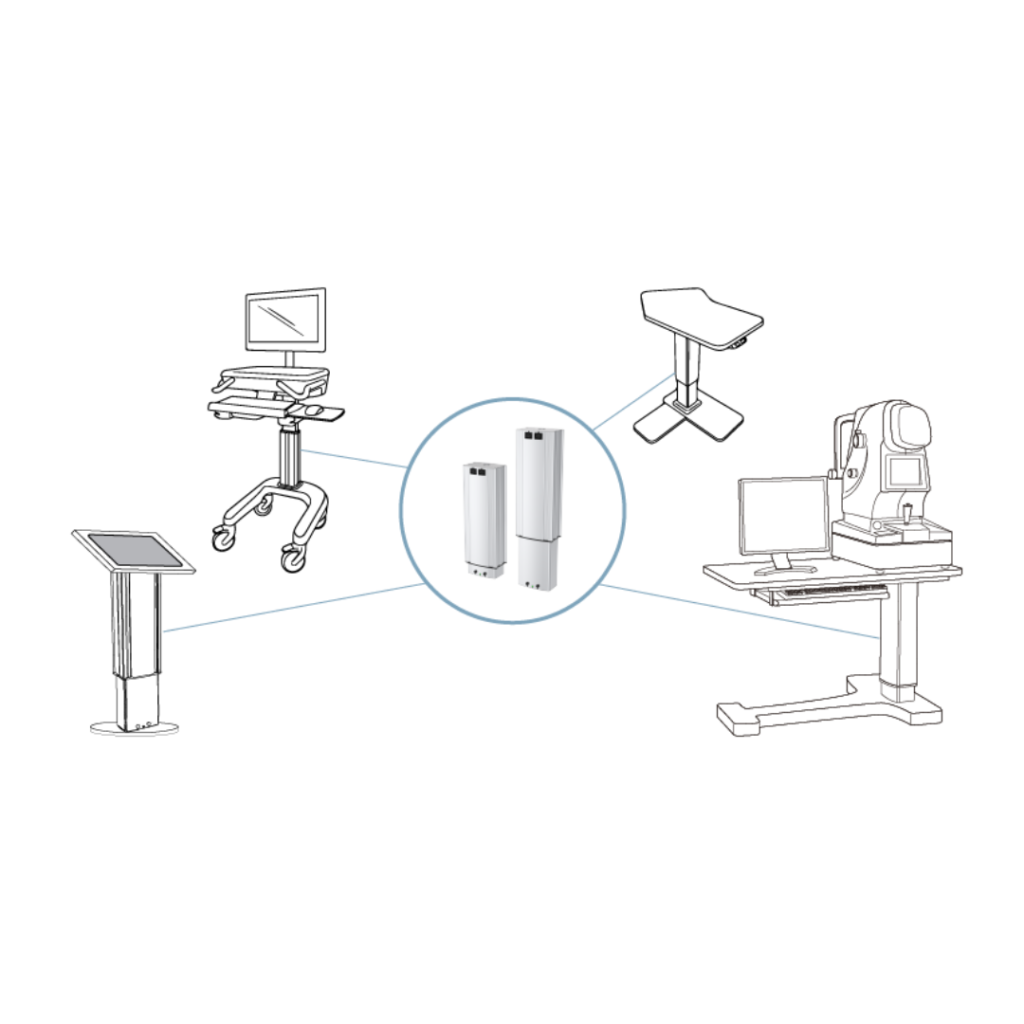

Customizable Configurations for Diverse Hospital Bed Designs

Every OEM has unique design goals. Polar’s actuator solutions allow manufacturers to shape their products exactly as they envision. Options include:

- Flexible stroke lengths for different bed segments.

- Varied load capacities and speed profiles, adaptable to ICU beds, ward beds, examination tables, and more.

- Programmable control features, enabling multi-function bed movements.

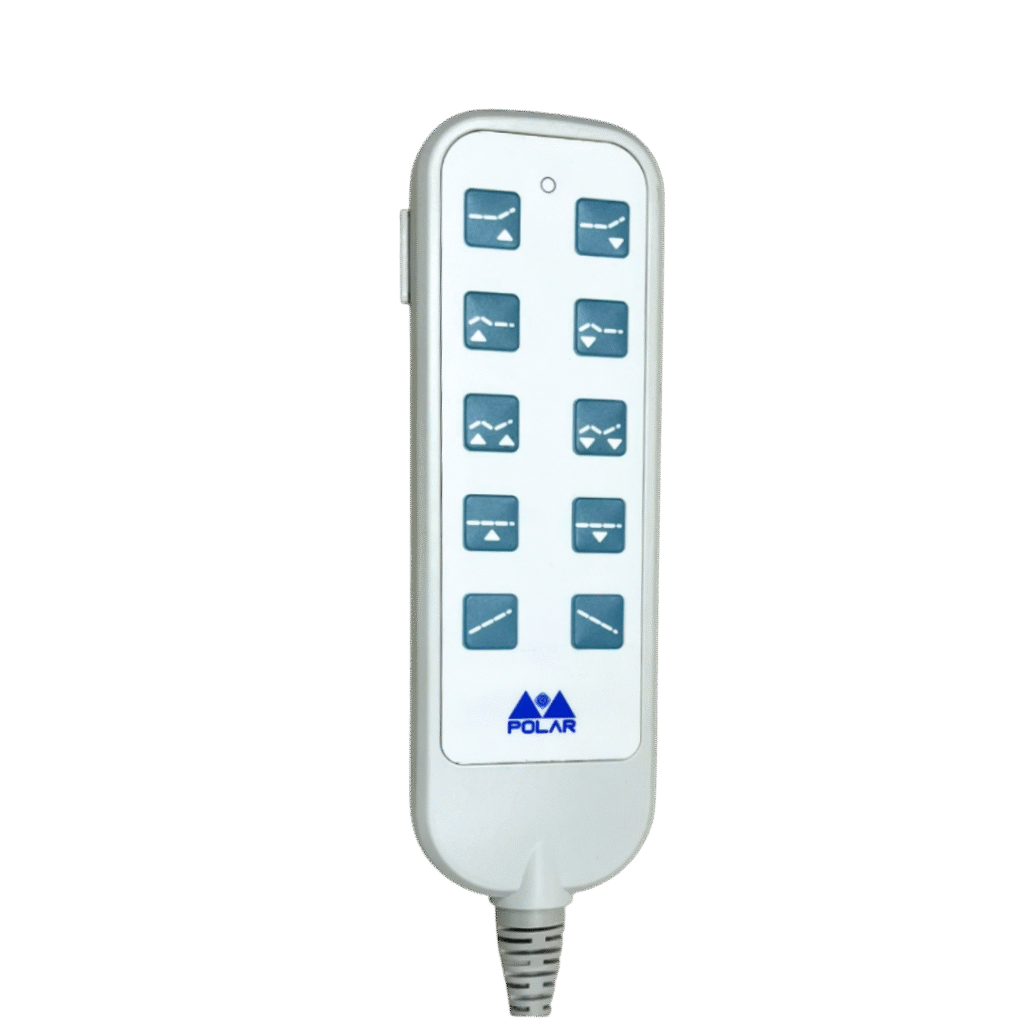

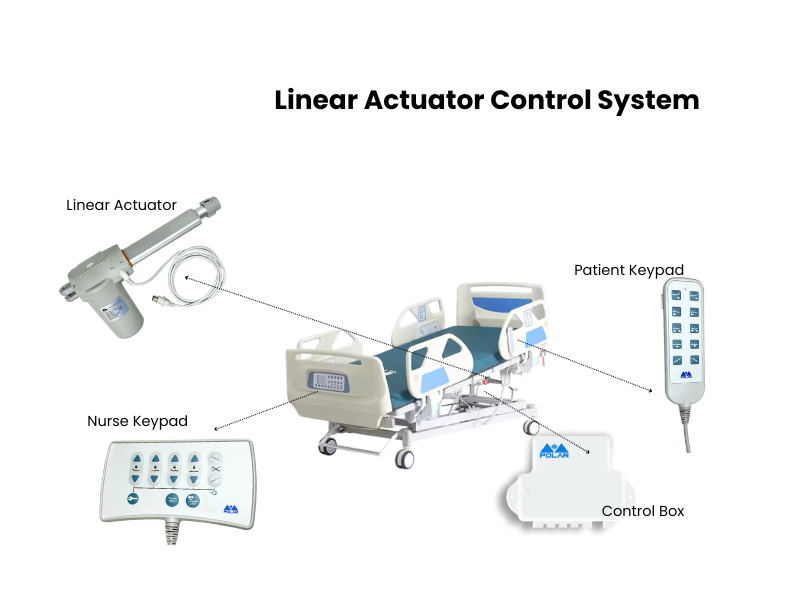

- Choice of remotes and control units, selectable based on ergonomics, user experience, and application.

This makes integration simple, fast, and efficient, without forcing OEMs to redesign their existing bed structures.

Intelligent Control Technology that Enhances Workflow

Polar’s advanced control systems are developed with a deeper understanding of hospital operations. They focus on:

- Reducing caregiver effort with easy, responsive control functions.

- Optimizing daily workflow through precise actuation cycles.

- Improving ergonomics, allowing smooth transitions between patient positions.

These intelligent systems contribute to better patient handling, shorter adjustment times, and improved caregiver productivity.

H2: OEM Branding and Customization Options for Hospital Beds Linear Actuator

A distinct market identity is essential for medical equipment manufacturers. Polar supports OEM branding by offering:

- Logo integration on actuators, controllers, and handsets.

- Custom labeling options, aligned with the OEM’s design style.

This allows manufacturers to maintain brand consistency across all mechanical and electronic components of their hospital beds.

DesignedH2: Made-in-India Hospital Beds Linear Actuator Engineering Excellence

& Made in India

Polar Automation takes pride in developing its actuator systems entirely in India—design, engineering, manufacturing, and testing. This results in:

- Strong quality control, since every core component is built in-house.

- Faster lead times, ensuring OEMs receive components on schedule.

- Better support and customization, thanks to a close, collaborative engineering approach.

This end-to-end control over production enables higher consistency and innovation speed.

Why Polar Continues to Lead in Hospital Furniture Automation

Medical professionals, hospitals, and equipment manufacturers trust Polar because the systems perform reliably where it matters most—patient care. Through continuous engineering improvements, deep application knowledge, and a focus on long-term performance, Polar delivers actuator control solutions that elevate every hospital bed design.

If you are looking to enhance your product line with precise, durable, and intelligently engineered automation systems, Polar’s solutions for hospital beds linear actuator applications bring strength, stability, and refined control—built for modern healthcare needs.