In the evolving medical industry, patient comfort and accessibility remain top priorities. A significant advancement in dialysis treatment is the use of Electric Actuators in Dialysis Chairs.

Polar Automation, integrates this technology into medical equipment, improving patient care and convenience.

Understanding Electric Actuators in Dialysis Chairs

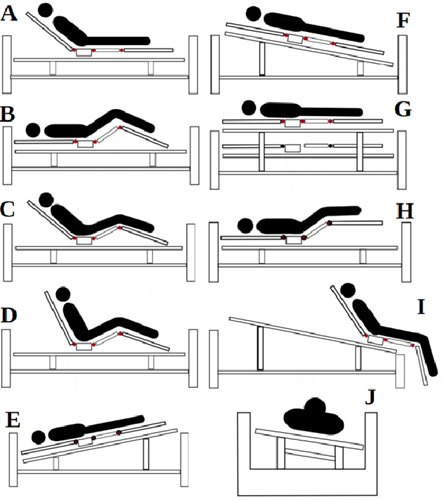

An Electric Actuator enables precise movements in medical chairs, including dialysis chairs. These actuators adjust the chair’s height, backrest, footrest, and tilt functions, ensuring optimal positioning for both patients and medical staff.

With growing demand for automated solutions in Indian healthcare, medical actuator solutions have transformed dialysis care. As a result, dialysis centers upgrade their equipment to enhance efficiency and patient experience.

Importance of Electric Actuators in Dialysis Chairs

Dialysis treatment requires patients to sit for long hours. Therefore, patient comfort, stability, and adjustability play crucial roles when selecting a dialysis chair. Electric actuators help achieve these factors.

1. Enhanced Patient Comfort

Firstly, electric actuators allow seamless position adjustments, reducing strain on patients who remain seated for extended periods. Smooth reclining and height adjustments contribute to overall comfort.

2. Improved Accessibility for Healthcare Providers

Additionally, a well-designed dialysis chair with motorized control ensures that medical professionals can easily adjust the patient’s position, facilitating better treatment access.

3. Customization Options

Furthermore, healthcare facilities can opt for a custom electric actuator setup that meets specific medical requirements. These tailored solutions improve the ergonomics and efficiency of dialysis chairs.

Dialysis Chair Specifications with Electric Actuator System

Before investing in a dialysis chair, understanding its specifications is essential. The inclusion of Electric Actuators enhances functionality. Key dialysis chair specifications include:

- Electric Height Adjustment: Ensures comfortable entry and exit for patients.

- Adjustable Backrest and Footrest: Provides ergonomic positioning for long dialysis sessions.

- Smooth and Silent Operation: Reduces noise in medical environments.

- Emergency Stop Function: Enhances safety for patients and staff.

- High Weight Capacity: Ensures durability and stability.

- Easy-to-Use Control Panel: Allows precise adjustments.

Factors Affecting Electric Actuators in Dialysis Chairs Dialysis Chair Price

Several factors influence the dialysis chair price:

- Technology Used: Chairs with electric actuator systems cost more due to automation features.

- Build Quality: Premium materials and reinforced structures increase the price.

- Customization: Custom electric actuators tailored to medical needs affect pricing.

- Additional Features: Battery backup, memory settings, and smart control panels add to the cost.

Why Choose Polar Automation’s Electric Actuators in Dialysis Chairs?

Without a doubt, Polar Automation, specializes in electric actuator systems for dialysis chairs. Their custom electric actuator solutions cater to diverse medical requirements, ensuring durability, precision, and patient comfort.

Key Benefits

- High-precision custom electric actuator technology

- Improved patient experience with ergonomic adjustments

- Advanced safety features with smooth operation

- Cost-effective solutions for Indian healthcare providers

- Durable and low-maintenance design

Future of Dialysis Chairs with Smart Automation

With the rise of smart automation in medical equipment, the demand for electric actuator-based dialysis chairs in India continues to grow. The Electric Actuator System transforms patient care, making dialysis treatment more accessible, efficient, and comfortable.

As healthcare technology advances, medical actuator solutions will play a vital role in shaping medical automation, ensuring better outcomes for patients and healthcare professionals.

Conclusion

To summarize, Electric Actuators in Dialysis Chairs enhance patient comfort and accessibility. Polar Automation ensures high-quality automation solutions, improving medical care. Whether considering dialysis chair price, specifications, or customization, investing in automated chairs leads to better patient experiences. The future of dialysis chairs centers around comfort, precision, and smart automation.